Heating protection

Water is life. What applies to people, animals and the plant world can also be transferred to hot water heating systems: the right filling water is the prerequisite for a long service life.

The most stringent rules here are set in the German VDI guideline 2035: In addition to the prevention of scale formation, water-based corrosion is the central topic. With good reason: Corrosion of the metallic boiler and pipe materials can cause serious malfunctions and damage. Corrosion products on boiler’s heat transfer surfaces worsen heat transfer and increase energy consumption. This can also result in damage to the boiler. Local overheating, malfunctions of control or thermostatic valves, increased wear of the circulation pump or malfunctions of heat meters may occur.

There should be a lot more between your drinking water and

heating system than just the word “and”

Clearly regulated by the standards, but in practice still far from being the rule: heating and drinking water must be kept separate. According to regulations such as EN 1717 and DIN 1988-100, the unsecured connection of the heating circuit to the drinking water network is not permitted.

Simple filling with a hose without safety device is a thing of the past. This is what the standards say. And also every satisfied customer who appreciates the convenience and safety of a high-quality filling valve.

How to meet the standards.

And the highest expectations.

Manufacturers have made great advances in heating technology in recent years. Condensing boilers, pumps and heat exchangers are operating more and more efficiently. But unfortunately, modern performance miracles are also becoming increasingly sensitive to the quality of the filling water.

This means that heating engineers and installers have to deal intensively with the subject of heating filling. First of all, the specifications of the heating manufacturers are decisive. Many now prescribe fully demineralised water – so there is no need for the heating engineer to compare processes. Furthermore, heating water treatment, as regulated in the german VDI guideline 2035. According to this guideline, both soft water and low-salt operation are possible. Both processes have their advantages and disadvantages.

Clean, stabilize, protect.

There is a dosing solution for almost every task.

In some cases, it may be necessary to condition the heating water. For example, German VDI guideline 2035 states: “In the case of aluminium materials in the system, further measures (e.g. dosing of inhibitors) may be necessary to prevent corrosion both during softening and desalination”.

According to this guideline, corrosion protection by means of inhibitors is even necessary in case of constant, unavoidable oxygen entry (VDI guideline 2035, section 8.4.3).

We have to get rid of

off impurities.

In new installations, it cannot be completely ruled out that dirt particles get into the heating system – for example due to material residues from production or contamination that occurs during installation.

However, various circumstances can also lead to contamination during operation.

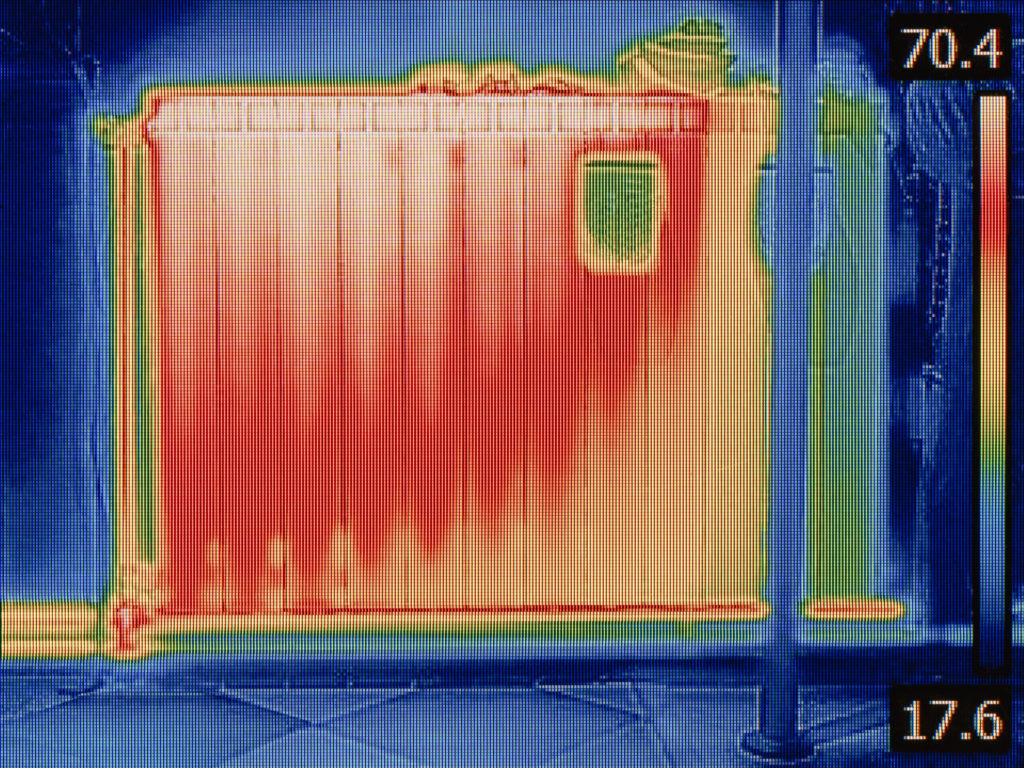

One of the main causes: oxygen, which unintentionally enters the heating system with small amounts of air.

Oxygen is highly reactive and forms compounds with various materials from pipes and components. The best known of these oxidation reactions: rust. Another, a kind of preliminary stage to corrosion, is the formation of magnetite sludge. Although it is not dangerous for pipelines, it can nevertheless cause considerable damage in the heating system.

To operate a heating system safely and efficiently in the long term, it is essential to remove both from the heating water: solid particles, especially magnetite – and air.

Inline water treatment

Without refilling.

In new plants, it cannot be completely excluded that particles get into the heating system, for example due to material residues from production or contamination that occurs during installation.

However, various circumstances can also lead to contamination during the operation of a plant. In some cases, it is necessary to treat the heating water – for example, after replacing the boiler or if the water quality requirements change. Ideally, inline treatment takes place without interrupting operation.

If faults occur in a customer’s heating system, quick solutions are required. It’s good if you have the right tools at hand. For example, a preparation system that is quickly packed and ready for operation in no time at all.

In addition, solutions for permanent installation are in demand, which ensure smooth operation of the heating system from the outset. For example, efficient heating filters.

© JUDO 2024 | All rights reserved.

© JUDO 2024 | All rights reserved.