Saving energy costs with properly treated heating water

So much potential lies in heating water

The cooler the temperatures in the autumn season and the closer the winter get, the more the topic of heating becomes present and, above all, the tremendous costs that will come our way this year. Increasing energy prices and an impending gas shortage are raising the fear that the heating situation in winter could literally become “frosty”. The current political and economic situation therefore places the onus on all of us to exploit every potential saving and to use our energy as efficiently and resource-saving as possible – whether in the private or commercial sector.

This makes it even more important, especially now, to bring the heating system up to scratch. There is great potential for savings here, which many consumers are not entirely aware of.

According to experts, reducing the room temperature by one degree already has a major effect in terms of the required energy consumption. But it is not just by operating the system and the direct savings linked to it that make a difference, but also the properties and condition of the heating water. Proper heating water treatment is now an integral part of the installation and operation of a system. With every deposit that forms, caused by limescale or corrosion, the efficiency of the system diminishes. On the one hand, this leads to a significant increase of the heating costs, and on the other, it also reduces the service life of the heating system. Experts estimate that for every millimeter of limescale (deposit) on the heat exchanger of the boiler, an energy increase of 10 percent must be taken into account.

Limescale and corrosion can be harmful

Limescale leaves its mark everywhere in everyday life. From the sink to the dishes to the kettle, washing machine and coffee maker. But limescale deposits also become noticeable in heating and piping systems – at the latest when the pipes get clogged, the heat transfer during water heating decreases or the water pressure drops. Worst case scenario: the pipe gets obstructed – and a pipe infarction occurs.

Another problem is the formation of corrosion. Corrosion can occur due to the interaction of various constituents of natural water, washed-in foreign particles and oxygen. Widely ramified pipe installations with little water movement and “mixed installations”, i.e., installations made of different materials, also favor corrosion, colloquially known as rust formation. The consequences: System components such as heat generators, piping, radiators, etc. are damaged, resulting in rusty, black heating water contaminated with magnetite. This can lead to leakage and thus water damage, and ultimately to replacement of the components.

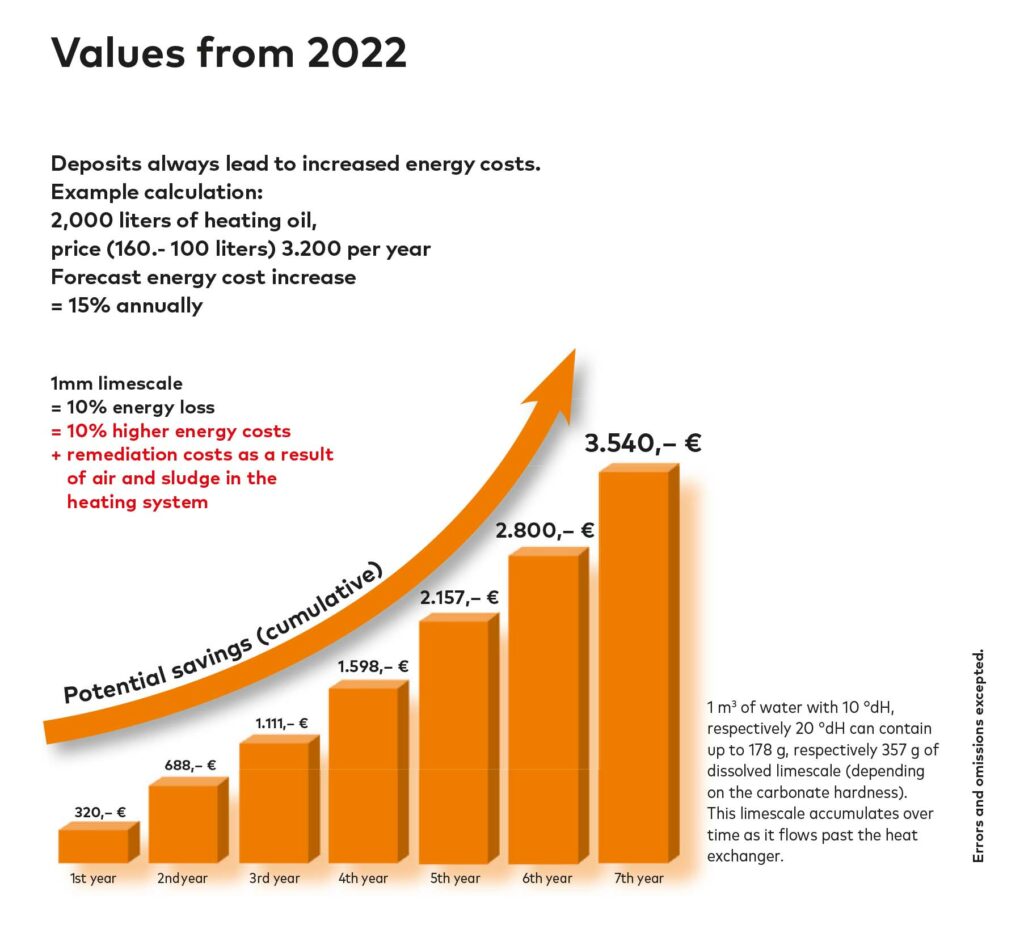

Sample calculation shows potential savings

The deposits and the corrosion-related damage simultaneously lead to progressively higher energy costs. 1 m3 of water with 10 °dH or 20 °dH can contain up to 178g or 357g of dissolved limescale (depending on the carbonate hardness). This limescale dissolved in the water precipitates by heating/heating the water at the hottest point of the heat generator and forms the deposit/insulation that interferes with optimal heat transfer. If we now take the estimated value of the energy increase of 10 percent, the following example calculation results for a heating system operated with oil:

Let us assume the annual consumption averages 2,000 liters of heating oil per year for a single-family house. The average peak oil price in Germany by mid-September was well over 160 euros per 100 liters. If one takes now exemplarily these standard values and leaves a nevertheless very probable price increase for 2023 out of consideration, that makes in the year around the 3,200 euro pure heating costs. If, in the next step, the possible 10 percent energy loss as a result of calcified or corrosion-damaged heating systems is added, this results in additional costs of around 320 euros in the first year alone. In the following years, the calculation below can then be made:

If no action is taken, the additional costs can increase significantly in subsequent years, as the buildup of deposits continues to reduce the efficiency of the heating system. In order to prevent such possible additional costs in an efficient way, it is essential to use the right filling and make-up water when filling the heating system, but also by the backfeed.

The right process is decisive

As far as the correct treatment of the filling and make-up water is concerned, the specifications of the manufacturers are decisive. These specifications are directly related to the nature of the material that is used. Many now specify fully demineralized water. In addition, the heating water quality is regulated in the guideline VDI 2035 Part 1 as a “generally accepted rule of technology”. Accordingly, both the high-salt mode and the low-salt mode are possible.

Water softening:

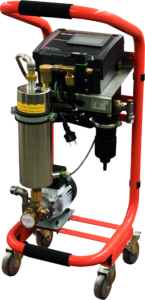

In the case of softening, only the hardness constituents calcium and magnesium are exchanged for sodium by the ion exchange process. Otherwise, the water composition and thus the salt content remain unchanged. For example, heating filling systems (JMHB) for softening, such as the mobile JUDO JMHB mini, are used being used. This unit provides standard-compliant filling and supplementary water without the hardness-forming agent lime. Pre-assembled on an agile frame with lockable castors, the JMHB mini is a convenient solution even where space is limited: – Simple and uncomplicated to use.

Regeneration takes place on site, thus enabling the filling of larger plant volumes.

Water desalination:

Water desalination by mixed bed cartridges is a process similar to softening. However, here, by means of ion exchange, all salts dissolved in the water are removed by a combination of cation and anion exchange resin. The result of this process is fully demineralized water. At the same time, the water hardness is reduced to 0°dH and the conductivity drops well below the value of less than 100 µS/cm required by VDI Guideline 2035.

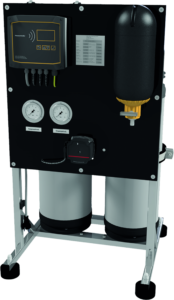

Another option for filling a heating system with desalinated water is a reverse osmosis system, such as the mobile JMHB-RO mini from JUDO. This ensures standard-compliant heating water quality with desalinated water (conductivity below 100 µS/cm). The continuously operating functional principle of the compact system enables the retention of all dissolved substances according to a physical membrane separation process, without further additives and regeneration.

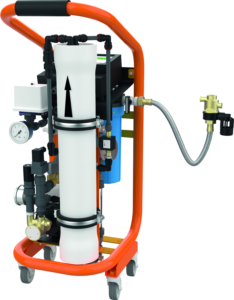

However, the treatment of heating water is not only useful for a new installation. Treated water can also achieve enormous savings in precious heating energy in existing systems. The JUDO HEIFI PURE & CLEAN combination system, for example, is suitable for filtration and desalination or softening of heating water in closed circuits. It consists of a high-efficiency circulation pump, a backwashable filter with deaeration system and a filling fitting as mains separation. The system treats the water in the so-called “inline process”, without draining, without refilling and without interrupting operation. It filters and desalinates or softens heating, cooling and process water in a single step.

It is not unusual for the heating system to suddenly gurgle when it is put into operation in the fall. This is mainly due to the presence of air or gases in the system. The consequences can be a lack of heat development and increasing heating costs. Venting the heating system provides a temporary remedy. A more comprehensive solution is to degas the entire heating water. JUDO offers the HEIFI-AIR-FREE degassing system for this purpose. This works on the principle of dynamic vacuum degassing. In this process, the water is sprayed in a container, whereby the pressure is lowered to vacuum beforehand. In these conditions, gases can no longer remain in a dissolved state and are released. Thus, the HEIFI-AIR-FREE brings the dissolved gas content (nitrogen and oxygen) of the water practically to zero. Another advantage: the JUDO HEIFI-AIR-FREE monitors the condition of the heating water and automatically starts further degassing when the need for it arises.

Contact:

JUDO Wasseraufbereitung GmbH

Pressestelle

Postfach 380

D-71351 Winnenden

Telefon +49 (0)7195 692 – 265

Telefax +49 (0)7195 692 – 245

E-Mail: presse@judo.eu

© JUDO 2024 | All rights reserved.

© JUDO 2024 | All rights reserved.