Training for the case of emergency.

A clean pleasure due to JUDO.

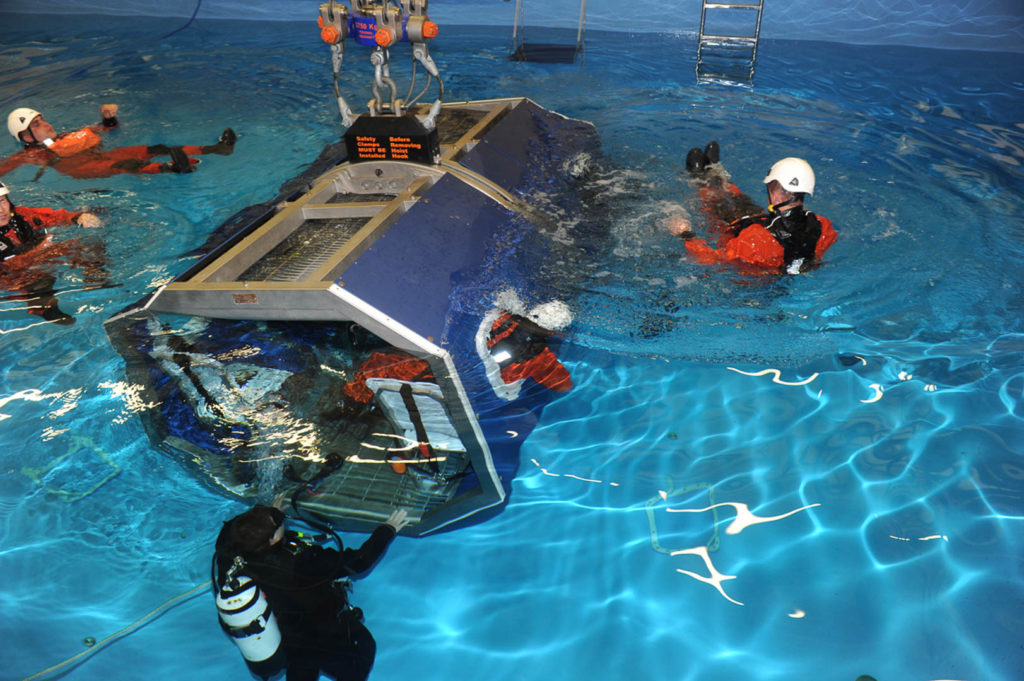

“Brace, brace, brace!” shouts the safety trainer as the helicopter cabin glides into the water with four passengers strapped in. These in turn quickly assume the so-called Brace position, a special body posture that provides protection against injuries in the event of an air accident. As soon as the passengers blow a deep breath of air into their breathing bags, the Emergency Breathing System (EBS), the entire cabin is not only under water but also turns 180 degrees. The passengers sit upside down. Now it’s time to stay calm! Still remain seated with their seat belts fastened, orientate themselves and breathe from the EBS until the safety trainer gives the signal to evacuate. Now push the window out, find a reference point, take another breath out of the EBS, out of the window – and off to the water surface. That’s it!

Falk Nutec operates worldwide as a professional provider of courses and consultancy.

This nerve-racking process takes only a few seconds. If carried out correctly, the right behaviour can save your life in an emergency. While in a real helicopter accident, panic quickly breaks out in the sinking cabin and everyone is on their own, passengers in this cabin have it a lot easier. They are participants in the “Helicopter Underwater Escape Training”, a safety training course that takes place in the safe basin of the Falck Nutec offshore training centre in Bremerhaven. These courses serve to prevent and manage crisis situations at sea. Successful participation is a must for personnel in maritime environments who often fly over water for professional reasons. The concrete goal of this course: bare survival in a helicopter crash situation at sea.

First the theory, then the practice.

The participants first learn the individual rules of conduct and the correct use of aids and rescue equipment in a detailed, half-day theory section. Only then is it time to put on safety equipment and get into the water – the exciting practical part begins. Of course, Falck Nutec has taken care of safety in the best possible way: each participant has a personal safety trainer at his or her disposal, and two rescue divers also monitor the course. “A certain amount of respect is quite normal in such exercises and also an advantage. After all, we practice for emergencies. But it is important that our course participants can absolutely rely on their personal safety. Above all, they should concentrate on the individual evacuation steps and internalise them,” says Sebastian Boeken, safety instructor at Falck Nutec.

Practice makes perfect, as is well known. And this is particularly important here, because in an emergency it must be possible to repeat the self-evacuation quickly and confidently – even under real conditions, such as darkness, in murky, salty or very cold seawater. However, Falck Nutec offers training under much more comfortable water conditions – at a pleasant 22 °C, clear and clean water, in a pool 8 m long, 15 m wide and 3.50 m deep.

Individual technology for clean pool water

The swimming pool technology from JUDO Water Treatment ensures perfect water quality. The task was to design, build and commission the complete pool water treatment system for the training facility.

The deep-sea training facility was built in a former shipyard hall, which is located directly on the sea and was completely gutted and renovated for this construction project. There was already a pool here, which had to be renovated, elaborately enlarged and stabilised. The corresponding, extensive swimming pool technology naturally had to be installed in the immediate vicinity. The JUDO experts quickly recognised where a particular challenge lay in this case: in the very limited space available. “Of course, there is never any off-the-peg technology for our large-scale projects anyway. For this project, a calculated circulation volume flow of around 56 m3/h was taken as a basis. In this case, we also had to improvise a little because we could only plan for a limited amount of space for our plant technology and the multi-layer filter system had to be installed on the upper floor of the building”, says JUDO. The existing technical rooms did not allow us to install the expansion tank that was actually necessary for the water treatment. These compensating tanks normally take up the sloshing and displacement water and provide the required backwash water for the filter system. Only after consultation with the responsible public health department was it possible to do without this tank. “No problem at all – we mastered this hurdle together with the local health authority by now taking the required filter backwash water directly from the basin”, explains JUDO. As a result, the overflow channel was selected so that wave slosh water from the pool is flushed directly into the sewer. The required continuous fresh water replenishment, which takes place directly in the basin via a special level monitoring system, was secured by a separate system separation. With this small exception, the design of the swimming pool technology was strictly based on DIN 19643, “Treatment of swimming and bathing pool water”.

Water filtration

At Falck Nutec, several training sessions are held every day, during which technical equipment, complete rescue equipment and other items are taken into the water, which can introduce additional contamination. Water filtration therefore plays an important role.

For this purpose, the pool water is sucked in from the front side of the pool with specially selected pool components that meet the DIN EN 13451 “Safety requirements and test methods for swimming pools” and fed into the JUDO GIGANT multi-layer filter system via a pipe system. This task is performed by the JUDO GIGANT circulation pump with upstream hair and fibre catcher, which is equipped with appropriate shut-off valves, pressure gauges and a frequency converter by means of which the pump speed is adjusted. A non-return cap integrated on the pressure side of the circulating pump prevents any backflow of water.

Before the water reaches the multi-layer filter system, it is inoculated with a polyaluminium chloride solution, which is taken directly and conveniently from the delivery container by a JUDO peristaltic metering pump and added to the calculated circulation volume flow. This solution is used for the continuous flocculation filtration prescribed in public baths. “With this technology, even finely dispersed particles and partially dissolved organic substances can be retained in the filter bed and then rinsed out. A simple filter system would only remove floating, solid and sedimentary matter – of course, this is not enough here,” explains JUDO.

Once it arrives at the GIGANT multi-layer filter system, the water is thoroughly cleaned. Specially arranged pneumatic single flap valves, which are controlled by a predefined program, ensure a controlled water flow: undissolved, visible or flocculated contaminants are retained both on the filter bed surface and in the depth of the filter bed. These particles are removed from the filter bed again by a time and differential pressure controlled backwash – as required by DIN 19643, with a flow velocity of 55 m/h. In addition to general requirements for swimming pool filters, the standard also describes the process combination of adsorption-flocculation-filtration-chlorination. Due to the low trihalomethane formation potential in the filling water, a separate adsorption process was not necessary in this case. The upper, coarse-grained anthracite layer serves as a depth filter with a low pressure drop increase, ensures a longer filter running time and prevents filter breakthrough. The existing porous surface structure of anthracite allows even the finest dirt particles to be adsorbed. The lower, fine-grained quartz sand layers have specific properties in their grain size and density and retain even the finest particles.

Water Hygiene

Absolutely stable, hygienic water conditions are a must – around the clock. To ensure this, various additives are added to the water: A GIGANT dosing system consisting of three dosing pumps inoculates liquid chlorine as well as pH value correction agent (pH value reducer/lifter) fully automatically and as required into the supply line. The dosing system is controlled by an automatic JUDO GIGANT measuring and control system that continuously measures the water parameters chlorine, pH value and redox potential and regulates the dosing of the additives accordingly.

With regard to water hygiene, not only the disinfection system but also the circulating volume flow to be introduced plays a decisive role. In the case of a rectangular basin normally designed quickly, the design of the vertical bottom inflow proved to be a challenge in this case: “There are some static points in the basin that we had to take into account in our planning: the basin stabilization and also technical equipment that had to be fixed to the basin floor. The vertical floor inflow therefore had to be planned in such a way that it was optimally integrated into the fixed points and dead zones (standing water) were avoided,” says JUDO. To enable the necessary flow through the pool, the experts used the so-called deer antler piping, which ensures an even inflow throughout the entire pool. In order to ensure this even more consistently, inlet nozzles were used, among other things, which could be varied in the flow rate.

Pool water heating

While people in distress at sea are mainly confronted with extreme cold, the participants of the safety courses are much more comfortable here. On the part of Falck Nutec, the specification for the pool water temperature was 20 to 22 °C. The technical possibilities of pool heating are manifold. However, the simplest and at the same time most cost-effective variant proved to be the most suitable one: “We were able to keep the system costs absolutely low and make optimum use of existing resources – we connected the pool water heating system to the existing building heating system. Here the pool water temperature is continuously measured and monitored by a separate JUDO GIGANT heat exchanger with integrated temperature sensor,” explains JUDO. “Thanks to this method it took only two days to implement the entire initial heating of the pool”.

Control center

The heart of the swimming pool water treatment system was installed right next to the filter system: the GIGANT control centre, where all functions for optimum operation come together. Via the password-protected control panel, which is equipped with operating hours counter and fault message history, filter times can be programmed and operating states and fault messages can be displayed. The integrated level control regulates the fresh water replenishment of the pool as well as the dry run protection of the filter circulation pump.

The frequency converter integrated in the control centre keeps the required circulation volume flow constant and controls the backwashing capacity. At night, the frequency converter automatically reduces the circulation capacity after a predefined time. This enables Falck Nutec to operate in a cost-saving and energy-efficient manner.

© JUDO 2024 | All rights reserved.

© JUDO 2024 | All rights reserved.